CORE AND MOULD MAKING FACILITY

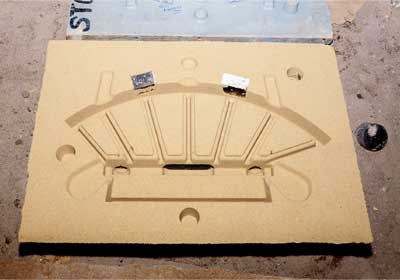

- Sand Muller and Sand Mixer with 450kg & 50kg.

- Co2 sand process (Core and Mould).

- Air Set Process - Core.

MELTING FACILITY

- Induction Furnace: 250kW Medium Frequency (Inductotherm).

- 2 Crucibles (500kg, 300kg).

- Silent Screw Compressor.

- Ladle Pre-heater.

- EOT Cranes.

HEAT TREATMENT FURNACE FACILITY

- Electrical Heat Treatment furnace with Capacity of 3 Ton.

- Size : 1650mm X 1250mm X 1000mm.

- Quenching Facility with 50 KL.

- Calibration with API 6A ANNEXURE M / API 6D ANNEXURE F / ASTM A991 / A991M.

SHOT BLASTING FACILITY

- Shot blasting machine is utilized to achieve good surface finishing.

FETTLING FACILITY

- Welding rectifier with Electrode stabilization Oven and Electrode holding oven.

TESTING FACILITY WITH DIFFERENT MACHINES

- Universal Testing Machine with Electronic Type

- Capacity: 40 KN.

- Extensometer.

- Calibration standard as per ISO 7500 – Part1.

- Brinell Hardness Machine

- Capacity: 3000 kg

- 5mm and 10mm indent ball.

HARDNESS TESTING FACILITY

- Rockwell Hardness Machine

- HRB / HRC Hardness Scale.

IMPACT TESTING FACILITY

- Impact Testing Machine

- Capacity: 300 Joules

- Calibration standard as per ISO 148 – Part 2

- Charpy V Notch.

- Testing Temperature up to sub zero (-196°C) using liquid Nitrogen.

LABORATORY TESTING FACILITY

- Optical Emission Spectrometer Fe + Ni Base- 29 Elements with Nitrogen.

WET LABORATORY AND OTHER TESTINGS

NON DESTRUCTIVE TESTING

Magnetic Particle Inspection